EtherCAT®: The fast and deterministic Ethernet fieldbus for industrial automation and robotics

2025-09-28

In the field of industrial automation and motion control, there is a crucial need for communications that are not only fast and reliable, but also deterministic. EtherCAT® (Ethernet for Control Automation Technology) is a leading solution that meets these needs by extending the capabilities of standard Ethernet for real-time applications.

Originally developed by Beckhoff Automation, a major manufacturer of PLCs (programmable logic controllers) for industrial automation and real-time control systems, EtherCAT® has become a leading solution in this field.

EtherCAT® technology was introduced worldwide in 2003. In 2004, Beckhoff donated the rights to the technology to the EtherCAT® Technology Group (ETG), an organisation responsible for promoting and developing the standard ever since. Today, the ETG is the world's largest Industrial Ethernet user organisation, with over 6,500 member companies from 69 countries. EtherCAT® has been internationally standardised since 2007 in the IEC 61158 and 61784 series of standards, as well as in ISO 15745-4. The drive profile is standardised in IEC 61800-7. The extension for functional safety, 'Safety over EtherCAT®' (FSoE), was internationally standardised in IEC 61784-3-12 in 2010. EtherCAT® is also a national standard in countries such as China (GB/T 31230) and South Korea (GB/T 36006 for Safety over EtherCAT®).

Although EtherCAT® is based on the physical and data link layers (layers 1 and 2 of the OSI model and IEEE 802.3) of standard Ethernet, its operating principle and use of the upper layers of the OSI model are what make it suitable for real-time applications.

Standard Ethernet was originally conceived as non-deterministic and was therefore not initially suitable for real-time control. Its protocol allows data packet collisions. EtherCAT®, on the other hand, is optimised for deterministic communication. It uses a master-slave architecture in which only the master sends telegrams. The slaves then process these telegrams and insert their own data. This eliminates the collisions inherent in standard Ethernet.

Aiming to create an even simpler and more economical system, unlike traditional Ethernet, which typically requires switches, EtherCAT® does not require switches or hubs in most configurations. It supports a variety of topologies (line, tree, ring, star or combinations) without any loss of performance. The ring topology allows for cable redundancy. The distance between two nodes can be up to 100 metres with standard cables and can be extended to over two kilometres with fibre optics.

Furthermore, the EtherCAT® master can automatically detect changes in topology and address slaves, thus eliminating the need for manual addressing. It can also manage the 'hot' connection and disconnection of nodes (Hot Connect). The diagnostic system quickly and accurately detects disturbances and identifies critical segments via error counters.

The fundamental difference with respect to Ethernet is 'processing on the fly'. Rather than each node receiving, interpreting, and copying the entire data packet, as occurs in standard Ethernet, an EtherCAT® network sees the master send a telegram containing data for all slaves. As the telegram passes through each slave device, the device reads the addressed data and inserts its own data (e.g. input data) into the same frame while it is still moving. This eliminates processing delays at each node and maximises bandwidth utilisation.

To achieve fast cycle times, EtherCAT® bypasses the network (IP) and transport (TCP/UDP) layers of the Ethernet OSI model entirely. However, these IT protocols can still be 'tunnelled' over EtherCAT® if necessary, in a process known as Ethernet over EtherCAT® (EoE).

To be more accurate EtherCAT® employs a distributed clock mechanism (Distributed Clocks – DC) that enables extremely precise time synchronisation among all slaves. Jitter (delay variation) is typically less than 1 µs and often measured in nanoseconds (less than 100 ns). This level of precision is equivalent to that of the IEEE 1588 PTP (Precision Time Protocol) standard, and no special hardware is required in the master. The slaves latch onto the clock time of the first slave in the telegram and use this as a reference to adjust their own internal clocks.

In summary, while standard Ethernet is flexible for non-time-critical data transfer, EtherCAT® is optimised specifically for the deterministic, real-time communication required in control and automation applications. It offers high performance and precise synchronisation without the complexity of switches or the non-determinism of traditional Ethernet, and provides topology flexibility.

Standard Ethernet tools, on the other hand, can be used for monitoring data traffic.

Main applications of EtherCAT®

Thanks to its high speed, determinism, and reliability characteristics, EtherCAT® is an ideal solution for a wide range of applications in industrial automation and beyond:

Motion control: It is considered the fastest real-time industrial Ethernet protocol available and is particularly suitable for high-performance motion control applications where speed and synchronization are crucial.

Industrial automation: It is widely used to interface with various field devices such as motor drives (servo drives), I/O systems, sensors, valves, vision systems, and mechatronic components.

Robotics: It is widely used in robotics, including industrial, medical, and humanoid robots.

Measurement systems and data acquisition (DAQ): The advanced protocol features allow efficient synchronous data throughput in distributed measurement systems. EtherCAT®-compatible DAQ systems can provide real-time data to master controllers or function as controllers themselves.

Demanding applications: It is used in sectors requiring high precision and reliability, such as semiconductor manufacturing, packaging machines, printing machines, power plants, test benches, wind turbines, tunnel control systems, and safety systems.

EtherCAT® in robotics

Advanced and service robotics, in particular, require real-time performance, a high dynamic response and multi-axis coordination. Motion control is fundamental to robots and depends heavily on communication technology. Indeed, modern robots are not viewed as individual axes, but rather as integrated systems capable of dynamic and synchronous movement. This necessitates cycle times of less than a millisecond and precise synchronisation for scanning positions and controlling multi-DOF (degrees of freedom) systems. EtherCAT® is in a leading position for these applications thanks to its high speed and precise synchronisation, achieving jitter below 100 ns even in networks without a precision clock in the master as nodes share the clock time.

In robotic systems, EtherCAT® is often used to connect the main controller to motor drives (servo drives) and I/O systems, for example. The flexible topology of EtherCAT®, which supports line, ring, tree, star, and combinations, fits well with the physical structure of robots and the need to integrate sensors and tools.

GigaDevice's approach and solutions for motor control in robotics

Robots have many degrees of freedom and joints, each of which has specific load requirements. In order to complete an action, the various joints must coordinate precisely. Two key points must be emphasised: first, the hardware design of each individual joint must be excellent; second, a closed-loop real-time network system must be formed between the joints for efficient communication, usually using the EtherCAT® standard.

Some customers use over 20 high-end MCU cores (M7 and M85), as well as more than 10 middle-end MCU cores (M4 and M33), to handle different joint tasks. These joints communicate via built-in buses to ensure synchronisation of motion and data between each joint.

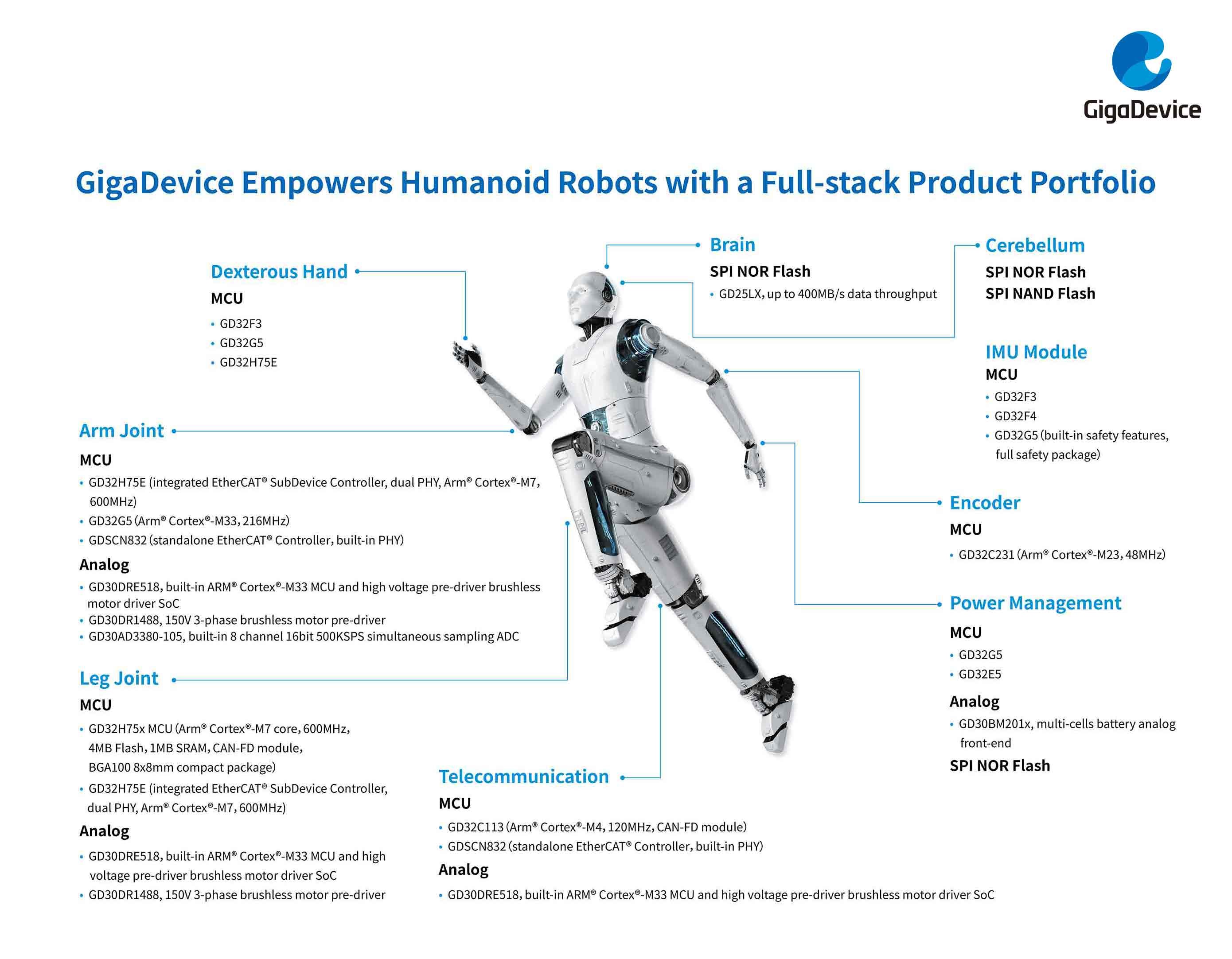

GigaDevice provides a wide range of products, including microcontrollers, flash memories and analogue chips, offering a 'full-stack' approach to automation and robotics, particularly with regard to the emerging requirements of robots.

Robots impose stricter requirements than traditional motor control in terms of high dynamic response, multi-axis coordination, energy efficiency and real-time communication.

To meet these needs, GigaDevice has developed specific hardware solutions; in fact, their MCU solutions are designed to meet the diverse control requirements of a robot's various joints.

GigaDevice's proposed control architecture for robots involves using high-performance MCUs (M7 and M33 cores) in each joint or group of joints. These MCUs communicate with each other via integrated buses, often based on the EtherCAT® standard, to ensure motion and data synchronisation.

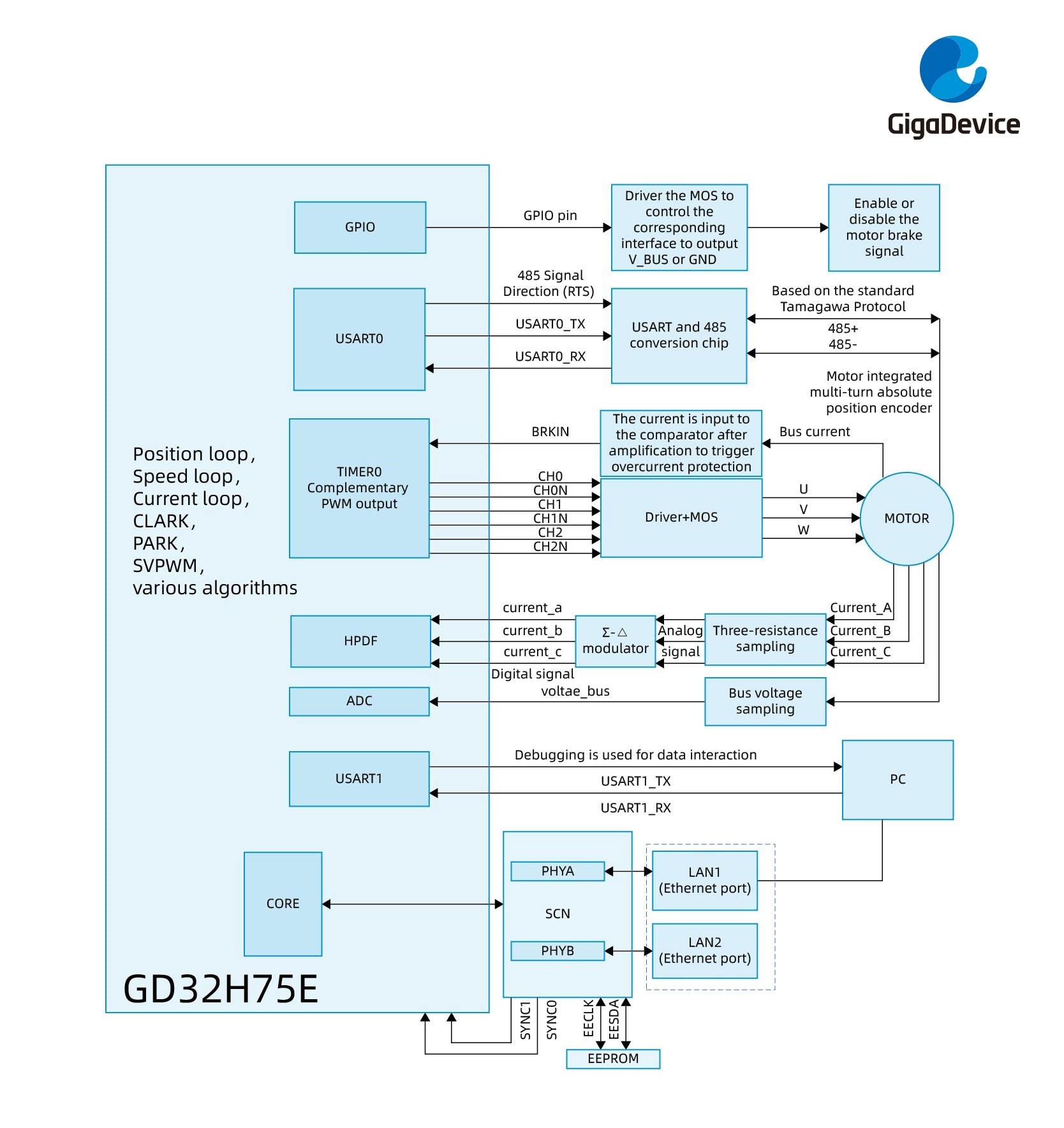

GigaDevice offers the GD32H75E MCU, which is based on a powerful 600 MHz ARM® Cortex®-M7 core. This MCU provides significant processing power for real-time control. It integrates an EtherCAT® SubDevice controller and two internal PHYs, as well as FPU/DSP hardware accelerators to support high-dynamic servo control and complex motion control requirements. The GD32H75E supports a dual EtherCAT® + CAN FD bus architecture. This architecture is designed to ensure microsecond-level, multi-axis synchronisation, reduce communication latency and enable high-speed data interaction between a robot's multiple joints.

Gigadevice offers also the GD32G5 MCU series (with a 216 MHz ARM® Cortex®-M33 core) for tasks requiring sensor control and actuation with a real-time response of nanoseconds. Optimised for robotic sensing and execution systems, this series features high-precision ADC/DAC and high-resolution timers for precise control signals, as well as a programmable set of lookup tables for fast, deterministic, and customisable behaviour.

Even if the GigaDevice MCU portfolio can satisfy the requirements of the market from a hardware viewpoint, the increased use of robotics in industrial and consumer markets will also pose significant safety risks, as frequent failures can have serious consequences. This is similar to the safety challenges faced by autonomous vehicles. Therefore, robot design must consider the functional safety of the entire product holistically, just like intelligent cars. The overall electronic/electrical architecture must be systematically planned, and certain functional safety requirements must be set for each component. Only by implementing such comprehensive safety measures can safe and reliable commercial applications be realised.

In addition to functional safety, information security must also be highlighted, as this is an issue that is easy to overlook. No robot manufacturer wants their systems to be compromised. To solve this problem, robust industry standards, comprehensive laws and regulations, and collaboration between hardware and software providers throughout the industry chain are needed to eliminate safety risks.

It is worth mentioning that GigaDevice has developed targeted solutions for both functional safety and information security to ensure the safety of customer chips.

The company focuses on functional safety, complying with standards such as IEC 61508 and ISO 10218, and offers comprehensive support packages including a Safety Manual, FMEDA and self-test libraries. The company also addresses information security with specific hardware features to protect code, ensure secure boot, secure debugging, and secure firmware updates.

Unlike traditional solutions, which may use less efficient fieldbuses or less synchronous and distributed architectures, GigaDevice's approach involves integrating high-performance EtherCAT® into their MCUs and emphasising deterministic multi-axis communication. This enables the company to meet the higher control requirements and precise coordination needed by modern robots. The company is positioning itself as a key chip supplier for the anticipated mass production of robots in the coming years.