Unlocking the Smart "Core" Power Inside Robotic Vacuums

2025-05-16

GigaDevice empowers robotic vacuums with advanced chip technologies and intelligent solutions—driving a new era of smart, seamless cleaning.

Robotics is no longer a futuristic dream—it's a fast-moving reality reshaping how we live, work, and interact. From smart home assistants and hotel service bots to warehouse automation and precision manufacturing, robots are showing up everywhere. And they're getting smarter. What once relied on simple pre-programmed tasks has evolved into intelligent autonomy. Today's robots don't just follow orders—they learn, adapt, and make decisions in real time. This shift is redefining the role of robotics, turning them from tools into intelligent partners across industries.

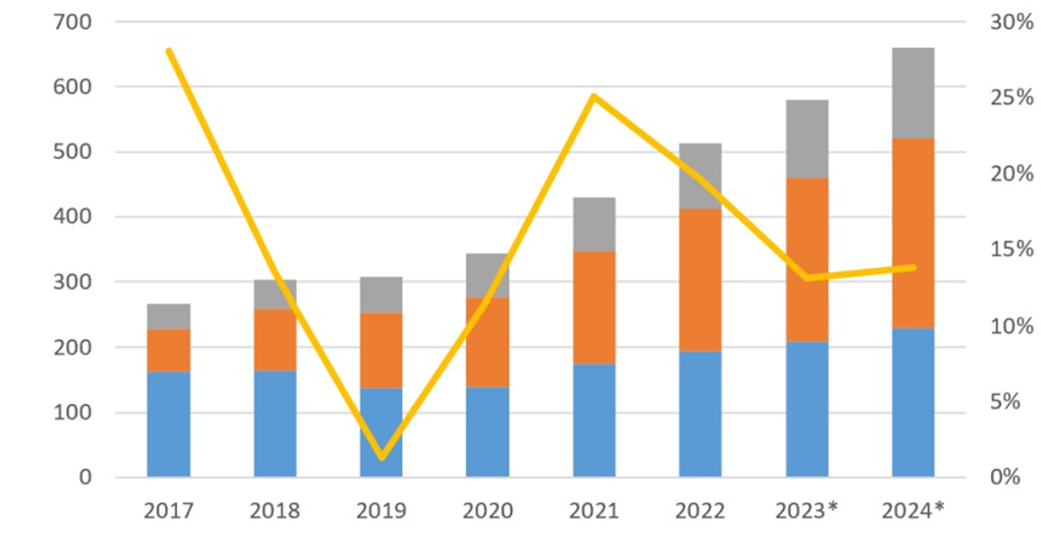

According to the White Paper on the Development of Intelligent Robotics Industry and Technology (2023 Edition), the global intelligent robotics market surpassed $50 billion in 2022 and is expected to exceed $66 billion by 2024. In China, as industrial digital transformation deepens, the intelligent robotics market is projected to reach $25.1 billion in 2024, with a CAGR of 20%. Industrial, service, and special-purpose robots will account for 50%, 35%, and 24% of the global market, respectively.

Global market size of intelligent robots (Source: IFR, CAICT, CES)

The Golden Decade of Smart Service Robots

Back in 2017, the China Academy of Information and Communications Technology, IDC, and Intel jointly released the white paper "The New Ecosystem of Robots 3.0 in the Era of Artificial Intelligence." This document delineated the evolution of robots into three eras: Robot 1.0, Robot 2.0, and Robot 3.0. The progression moved from robots lacking environmental perception and merely replicating human-taught actions in manufacturing, to those capable of intelligent collaboration, understanding, decision-making, and autonomous service execution in up to 90–95% of scenarios.

This development mirrors a multi-stage rocket model akin to the internet's growth. The first stage focuses on key scenarios, enhancing application specificity and expanding the user base. The second stage introduces human augmentation through continuous learning and scenario adaptation, gradually replacing human labor to meet user expectations. The third stage aims for scalability, integrating cloud-edge-terminal robotic systems to achieve mass commercialization at reduced costs

According to Chinese national standard GB/T 39405-2020, robots are categorized into industrial, service, and special-purpose types. Service robots—requiring close human interaction and adaptability to complex environments—present the greatest potential and urgency for intelligent upgrades.

In 2023, China's service robotics market reached approximately RMB 60 billion, with a five-year CAGR of 32.41%. Globally, the robotics market is expected to grow nearly tenfold by 2030, reaching $160–260 billion.

Among service robots, robotic vacuum cleaners stand out as the most widely adopted and best-selling category.

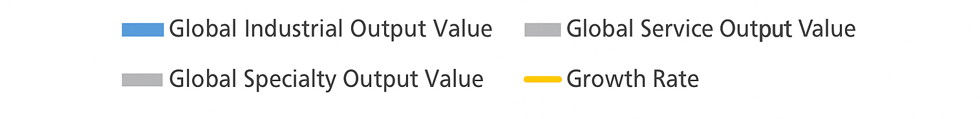

According to the 2024–2029 China Robotic Vacuum Industry Forecast Report by the China Business Industry Research Institute, retail sales of robotic vacuums exceeded 6 million units annually during their 2019–2020 boom. Though sales dipped in the following years, they rebounded in 2023 with 4.58 million units sold—a 4% year-on-year growth. In Q1 2024, retail sales reached 1.02 million units, up 17% year-on-year. Analysts forecast total sales to reach 5.25 million units by the end of 2024.

2019-2024 Robotic Vacuum Cleaner Retail Sales Trend Chart (Source: China Business Industry Research Institute)

To support this growth, China has introduced several policy documents such as the Guidelines on Promoting High-Quality Development of Light Industry, the "Robotics+" Application Action Plan, and the 14th Five-Year Plan for Robotics Industry Development, which all encourage innovation in smart home appliances and robotics.

GigaDevice Solutions for Robotic Vacuums

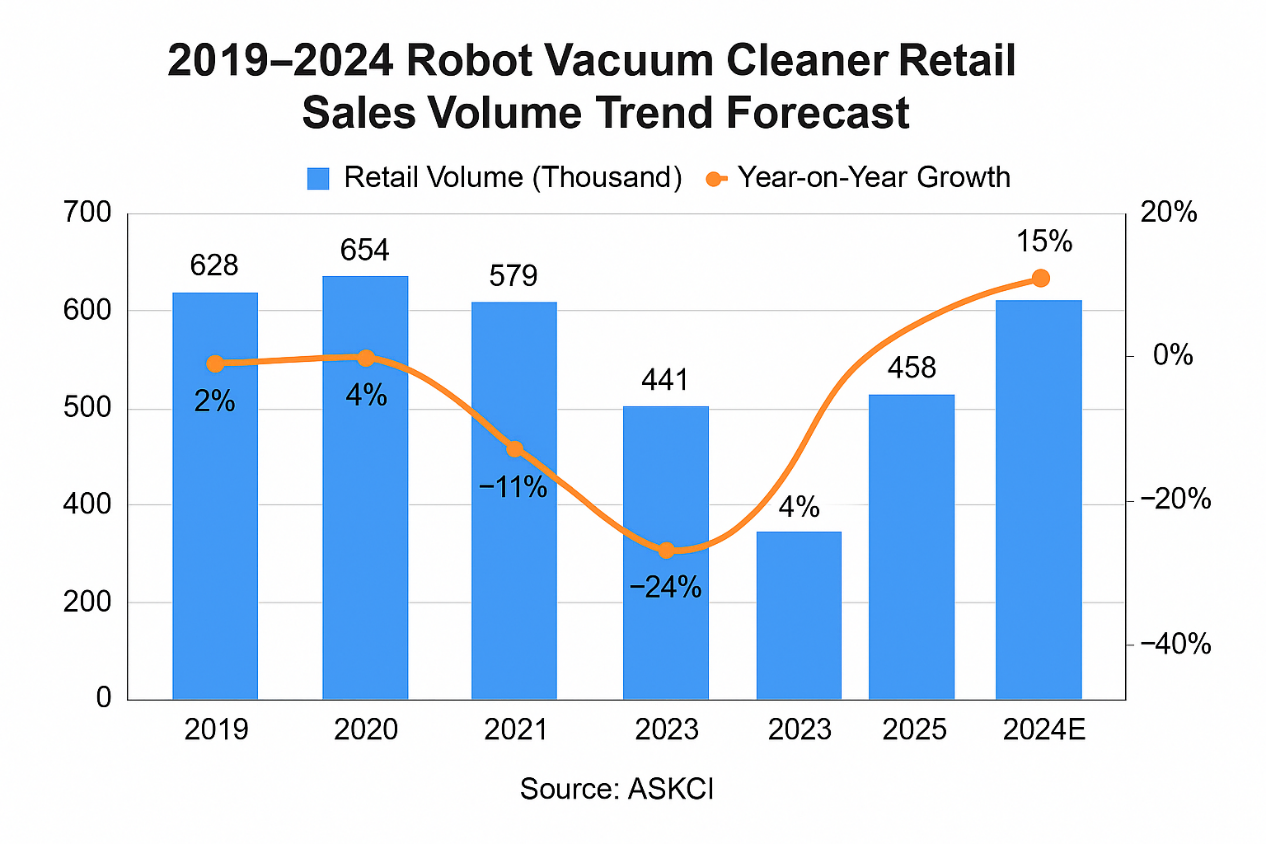

As a smart home appliance, a robotic vacuum's core competitiveness lies in its chip platform—where hardware and algorithms work in tandem to deliver exceptional performance. GigaDevice's diversified portfolio includes motor drivers, power management, battery charging, signal chain, microcontrollers (MCUs), and flash memory, and is widely adopted by leading brands in the robotic vacuum sector.

Robotic Vacuum System Overview

The system architecture can be divided into six core subsystems, each enhanced by GigaDevice's chips:

1. Mobility System:

The movement of the robot is powered by brushed motor driver chips, enabling agile motion and precise obstacle-avoidance steering. When encountering thresholds, carpets, or other obstacles, the system automatically adjusts and lifts the chassis to smoothly pass over, ensuring thorough and detailed cleaning in complex indoor environments.

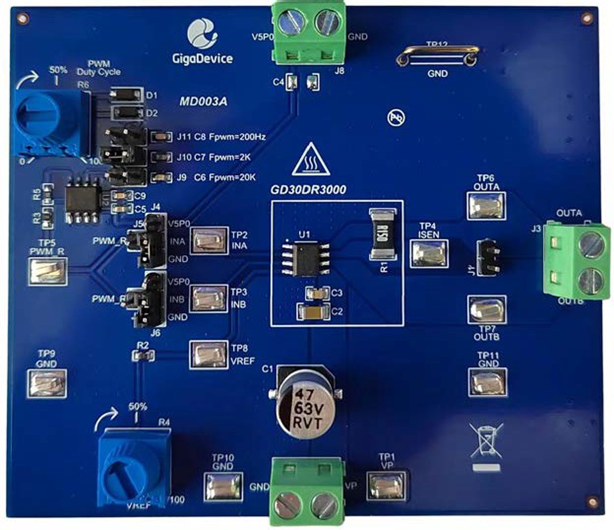

Recommended Model: Brushed Motor Driver Chip GD30DR300x

The GD30DR300x is a brushed motor driver integrating current sensing and fault protection features. It supports dual logic control channels and includes a bidirectional control circuit built with four high-current MOSFETs. Motor speed can be controlled via PWM with a frequency of up to 200kHz. It supports a wide input voltage range from 4.5V to 45V and offers a peak current of 6A. The chip provides comprehensive safety features, including over-current protection (OCP), thermal shutdown (TSD), under-voltage lockout (UVLO), and shoot-through prevention. This product is suitable for nearly all robotic vacuum system requirements, particularly for motor control in drive wheels—supporting forward/reverse motion, stall detection, obstacle avoidance motors, lifting mechanisms, and radar rotation control.

GD30DR300x Evaluation Board

2. Cleaning System:

Motor control chips manage the rotation speed and torque of the side brushes and main brush, as well as the wiping intensity of mopping cloths in hybrid sweep-mop robots. They also control the water pump output to ensure uniform mopping without water stains. Integrated with algorithms, these chips optimize suction while minimizing operating noise.

Recommended Model: Brushed Motor Driver Chip GD30DR300x

Primarily used for water pumps and electrolysis modules.

Recommended Models: Brushless Motor Driver Chips GD30DR8306/8413

This product series includes three independently controlled half-bridge drivers with a wide input voltage range of 4.5V to 30V. The GD30DR8413 model integrates the power stage and supports a peak drive current of 3A. Additional features include a built-in bootstrap circuit for high-side gate drive, under-voltage lockout, over-temperature protection, and shoot-through prevention, ensuring safety and reliability. Ideal for brushless motor applications such as the main brush, side brushes, and suction fans in robotic vacuums.

3. Power Management System:

This includes lithium battery charging, discharge control (MOS-controlled direct battery supply), AFE, and fuel gauge modules. Exceptional power management significantly improves device battery life.

Recommended Model: Lithium Battery Charger GD30BC2501

Robotic vacuums commonly use four lithium batteries in series. The charger chip, integrated either on the mainboard or in the charging dock, manages the charging curve to ensure efficient and safe charging. The GD30BC2501 supports 4/6 cell battery configurations, wide input voltage up to 32V, and charging modes including pre-charge, constant current, and constant voltage, with up to 5A switch-mode charging. Safety features include over-current protection, battery over/under-temperature protection, over/under-voltage protection, and thermal shutdown. Charging efficiency reaches up to 95%.

Recommended Models: DC-DC Buck Converter Chips GD30DC1350/1500

Commonly used for primary voltage step-down applications, with maximum input voltages of 28V/40V and output current of 3A.

Recommended Models: LDO Chips GD30LD2000/2010/240x

These low-Iq LDOs are ideal for standby low-power requirements.

GD30LD2000/2010: Used for secondary step-down, with max output of 300mA and 500mA respectively. GD30LD2000 features ultra-low quiescent current (0.8μA), ±2% voltage accuracy, shutdown current <0.1μA, and thermal and current protection.

GD30LD240x: High-voltage, low-power LDOs with input up to 36V/45V and output current between 250mA–350mA, suitable for primary step-down stages.

Recommended Models: Analog Signal Chain Chips GD30AP321/358/324, GD30AP8631, GD30CP331

GD30AP321/358/324: General-purpose op-amps

GD30AP8631: Medium-speed op-amp

GD30CP331: General-purpose comparator

Used for external motor current detection and feedback to the MCU.

4. Perception System:

To accurately recognize surroundings, avoid obstacles, and navigate efficiently, robotic vacuums integrate various sensors such as gyroscopes, ultrasonic sensors, DTOF (Direct Time-of-Flight), infrared sensors, and LDS (Laser Distance Sensors). High-precision sensor collaboration relies on efficient data processing chips to enable real-time environmental perception and accurate interpretation.

Recommended Models: Value MCU Series GD32E230/E235 and GD32F3x0

GD32E230/E235: Based on the Cortex®-M23 core, up to 72MHz, with 16KB–128KB Flash and 4KB–16KB SRAM. These chips offer strong ESD protection and interference immunity, ideal for acceleration sensors, Hall sensors, and ultrasonic sensors.

GD32F3x0: Cortex®-M4 core with excellent performance and rich peripherals, up to 72/84/108MHz, 16–128KB Flash, and 4–16KB SRAM. Suitable for LDS laser sensor data collection, processing, and control.

Both series offer software and pin compatibility, allowing flexible system selection.

5. Control System:

MCUs and SoCs serve as the central control units, responsible for algorithm execution and coordinating the seamless operation of functional modules. With data storage support, the main controller interprets sensor data, plans cleaning/navigation paths, and dynamically adjusts system states to ensure efficient task execution.

Recommended Models: Mainstream MCU Series GD32F30x and High-Performance MCU Series GD32E50x

GD32F30x: Cortex-M4 core, up to 120MHz, 128KB–3072KB Flash, 48–96KB SRAM. Features rich interfaces including UART, SPI, QSPI, I2C, I2S, SDIO, CAN, USB OTG FS, EXMC, and Ethernet. Supports efficient control of multiple independent modules, suitable for complex system development.

GD32E50x: Cortex®-M33 core, up to 180MHz, 128KB–512KB Flash, 80KB–128KB SRAM. Supports Dual Bank simultaneous read/write, integrated hardware TMU (Trigonometric Math Unit) for efficient computation, high-precision PWM output, high-performance ADCs, high-speed comparators, and advanced connectivity (USB OTG HS, CAN FD, SQPI). Features excellent noise immunity (ESD 6kV), ideal for data-intensive, algorithm-heavy industrial and consumer applications.

Recommended Models: GD25/55 Series SPI NOR Flash

Wide capacity range, clock speed ≥133MHz, 1/2/4/8-bit I/O, DTR support. Typically paired with voice and radar modules.

Recommended Models: GD5F Series SPI NAND Flash

Available in 1Gb/2Gb/4Gb capacities, 133MHz clock, built-in ECC. Often used with SoCs for navigation modules.

6. Docking Station System:

Typically features automatic dust collection, water refill/drain, mop cleaning, drying, and sterilization functions, further reducing household chores and freeing up users' time.

Recommended Model: Brushed Motor Driver Chip GD30DR300x

Mainly used for water pumps, drying, and hot air sterilization systems.

Recommended Models: Value MCU Series GD32E230/E235 and GD32F3x0

Used as control chips for docking station systems.

GigaDevice, with its comprehensive technology portfolio, outstanding product performance, robust ecosystem, and responsive technical support, has established a strong market presence in the robotic vacuum sector. Looking ahead, GigaDevice will continue to innovate and drive the intelligent development of this field.